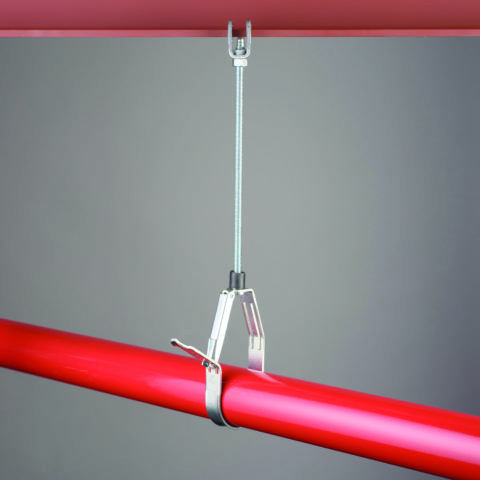

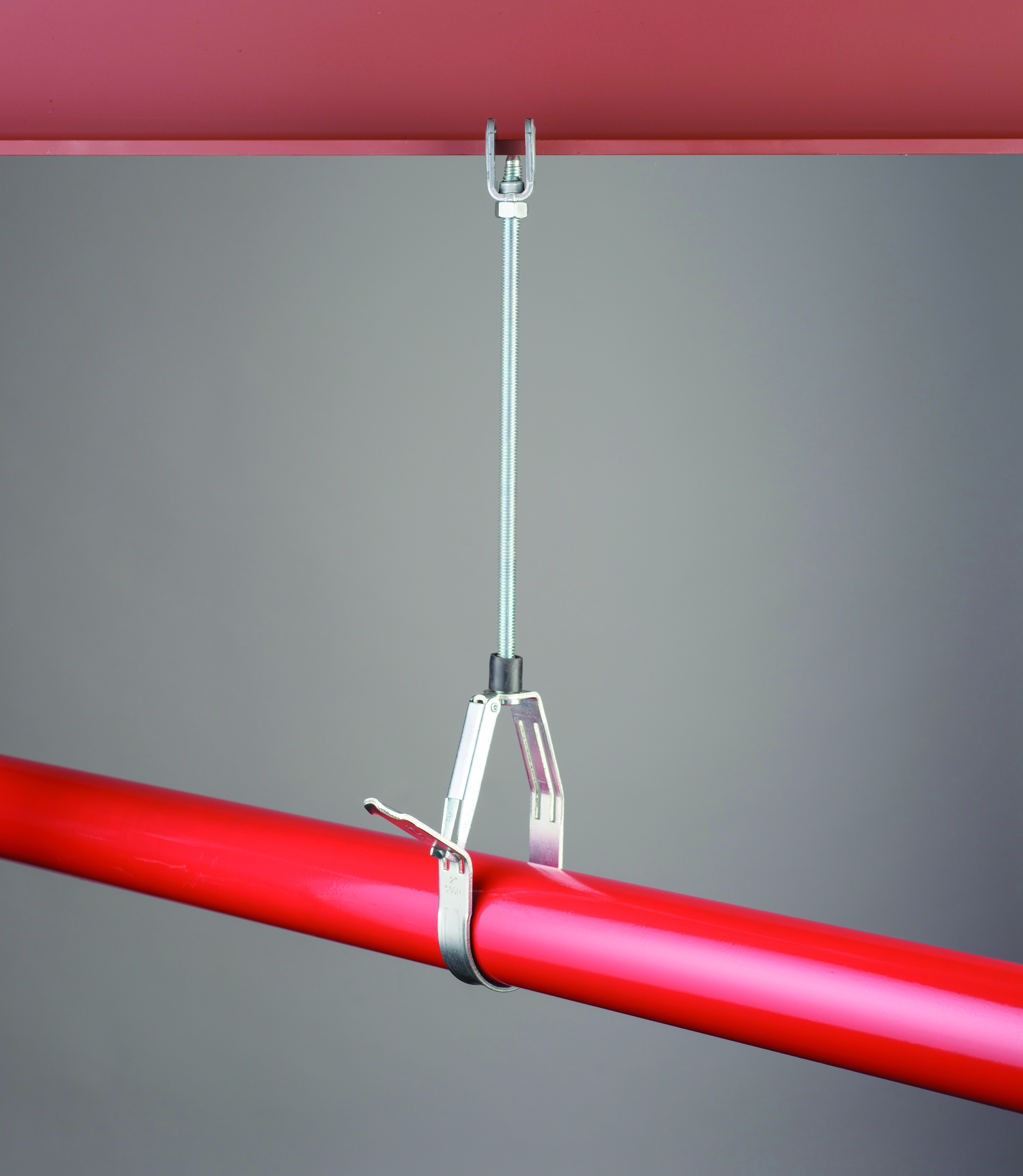

DROP-IN LOOP HANGER:

Traditionally, loop hangers have been commodity products that are mostly similar across manufacturers. Although they are low in material cost and sufficient at holding pipe, they can be very costly because of the long, tedious installation process. Most contractors typically install pipe by sliding each section through the hanger individually and then adding turns, sprinkler heads, and branch lines later. The whole process is timely and involves hours of dangerous overhead work.

The CADDY Drop-in Loop Hanger makes installation much simpler and quicker. Because the pipe does not need to slide through the hanger, large assemblies can be prefabricated on the ground and installed in one piece.

FOUR BENEFITS OF PREFABRICATING A SPRINKLER SYSTEM:

Previously, prefabrication with loop hangers was impossible. A properly sized loop hanger is the same diameter as the pipe that goes through it. Thus, installers were unable to prefab any fittings or pipe turns.

However, the Drop-in Loop Hanger accommodates more than just straight runs of pipe. Because the entire assembly no longer has to fit through the hanger, contractors are able to prefabricate features that were previously impossible. Being able to prefabricate a sprinkler system opens up contractors to numerous benefits. They include:

1. More Time to Prepare

Because many different trades need to work in the same space, there is typically a very short window of time that sprinkler installers have to complete their entire project. They need to quickly get in, complete the entire system and leave all within a scheduled time. However, when prefabricating, installers do not need to wait for access to the jobsite to begin working. They can attach sprinkler heads, turns and branch lines in the prefab shop. Once the site opens, they are able to quickly install all of the assemblies produced months earlier.

2. Profit Margin

Prefabrication reduces the amount of time spent on the jobsite during installation, allowing contractors higher profits on jobs and more jobs per year. In most sprinkler projects, labor is the largest part of the project’s final cost. Materials, in comparison, are much smaller. Reducing labor cost is usually the easiest way to increase profit margin.

3. Scrap Reduction

On the jobsite, pieces of pipe and small quantities of hardware are often discarded if they are not immediately useful. When assemblies are prefabricated in the shop, they produce significantly less waste because unused cuts of pipe and hardware can easily be stored and held for future projects. Reduction of waste results in cost savings and offers another way for contractors to save money.

4. Better Quality

Once the assembly is completed, it can be easily inspected and installed in one piece. One piece installation eliminates the need to rework projects and reduces the possibility of installation error.

CONCLUSION:

The Drop-in Loop Hanger revolutionizes the installation of pipe. Learn more about the product by clicking below.